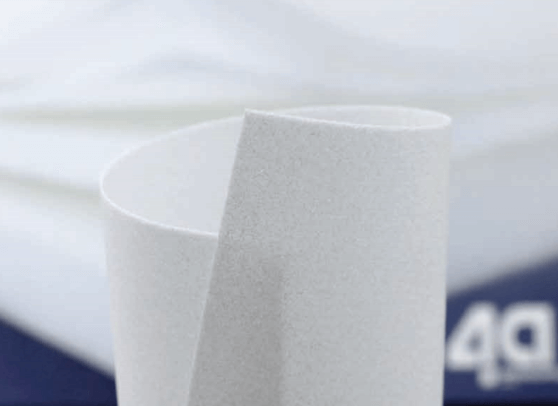

MILLIFOAM® - the world's thinnest high-quality hard foam sheets

The superior surface quality of MILLIFOAM® guarantees the highest product quality for our customers and is the result of our unique production process.

Advantages of MILLIFOAM®

MILLIFOAM®

An important factor for creating a high performance sandwich material is the choice of the right core layer. 4a manufacturing offers very thin hard foam sheets as core layers, which are called MILLIFOAM®. The advantages are not only better mechanical properties (stiffness to weight ratio), but in case of expensive raw materials (like carbon fibers) a possibility also of reducing costs by using a cheaper but still high performing core material. Our ability of processing commercially available polymers (PET, PVC, PPE, PMI, PESU,…) in an economic way, is allowing us to produce thin foam sheets very cost-efficiently. MILLIFOAM® is available in a world premiere new range of thicknesses, starting from 0.15mm.

The biggest advantages of MILLIFOAM® are:

The innovative process of 4a manufacturing allows to obtain these foam sheets in a newly state of the art surface quality and narrow tolerances, which combined with the higher flexibility allows a much easier processing, even for double-curved parts.

MILLIFOAM® core materials have shown compatibility with most of manufacturing processes like vacuum bagging, pre-preg processing, autoclave (even at high temperature and pressure), RTM, etc.